Czech transport company VCHD Cargo launched a new IT tool called Smart Trace Control. The tailor-made application alerts dispatchers about the emerging delays of vehicles and thus increases the transparency of the transport process for customers. It also allows the retrospective evaluation of all provided regular transports. Investments in information technologies including this new tool amounted to more than EUR 80 thousand this year alone.

VCHD Cargo has daily about 150 trucks across all Europe, mainly on regular long-distance lines. Planning the optimal route, tracking throughout the transport and the ability to predict the quality of delivery is one of the company’s top priorities. Investments in IT development are therefore a strategic objective for VCHD Cargo. Smart Trace Control was developed in cooperation with IT specialists from Unis computers. An application that connects customer order data with the GPS in the vehicle allows VCHD Cargo to proactively address non-standard situations in transport before their potential consequences are reflected on customer. It is also a unique quality management system for transport services.

“The true boosting force behind this project were our dispatchers. After the pilot start, they recognized the tool as a real helper that saves time and makes their job easier,” says Pavel Sirotek, Director of VCHD Cargo, adding, “when developing Smart Trace Control we received valuable advice from our colleagues from dispatching regarding changes and improvements. The result is a unique system for tracking and analysing transports.

Fast feedback for customers

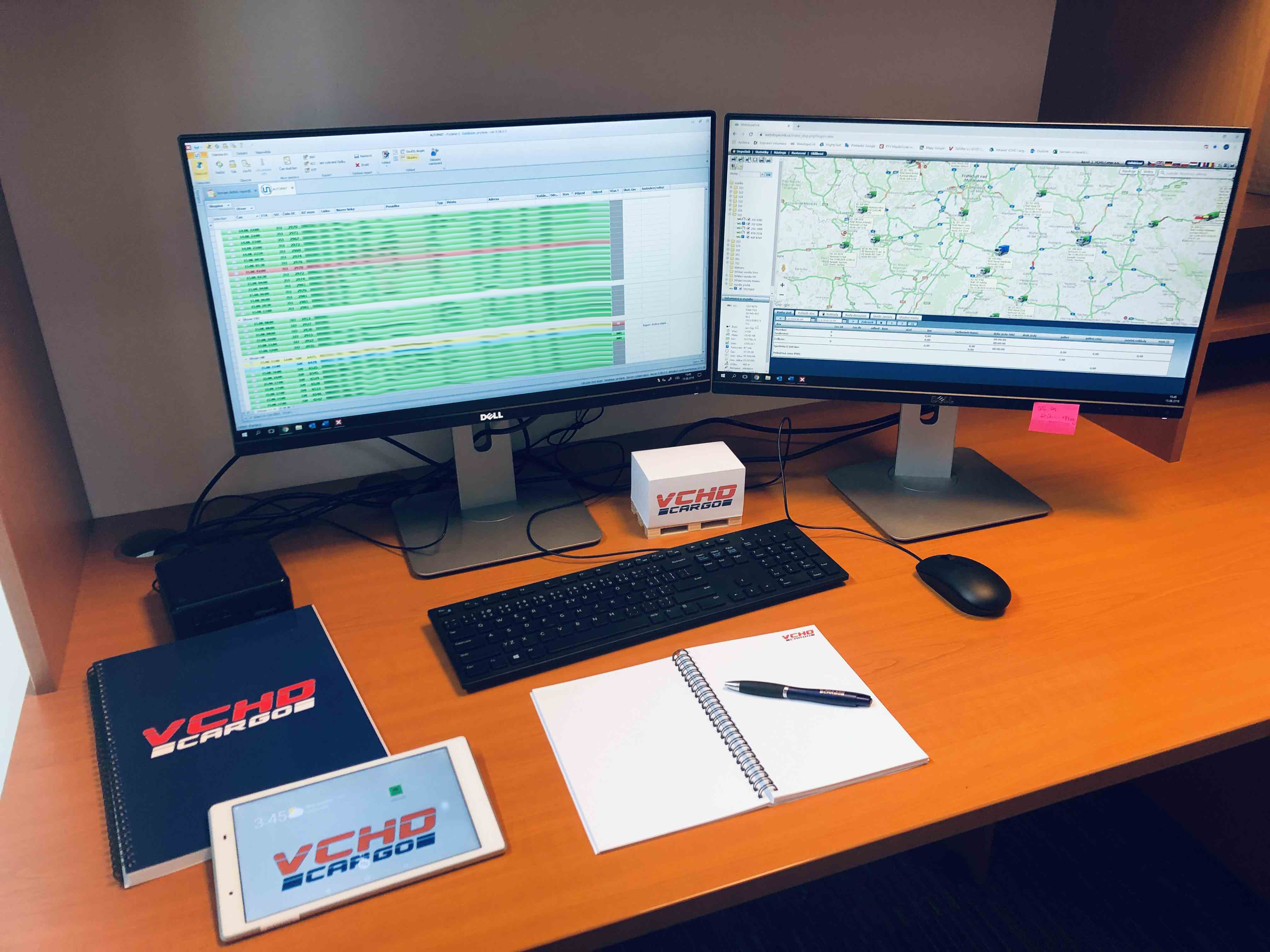

Today, thanks to Smart Trace Control, VCHD Cargo dispatchers have an interface on the monitor, which is strikingly similar to airport information boards – it records every regular transport line, its status and information are updated in cycles. Synthetic information from transport and tracing system, in which the planned time of arrival to designated place is compared with current geographical location of a particular vehicle enables easier communication of dispatchers with both the driver and the customer. It allows them to react in advance to any possible delays. For example, with serious traffic jam on the route, the dispatcher evaluates the situation as not manageable in given time, puts an entry in the application and informs the customer. Customer then has the opportunity to react – for example by prolonging the opening hours to enable the receival of shipments, he can also inform his end customers about the change in delivery date or possibly about the alternative solution in the production.

Transparency for dispatchers

In the context of statistical processing, various non-standard situations are categorised using a codebook. A registered obstacle becomes an organic part of the entire route and its subsequent stops. All dispatchers have this obstacle displayed in the system without the need for manual transmission of information. A comprehensive overview of problems, notes and messages is then provided by an auxiliary report, which allows the dispatcher entering the service to get very quickly acquainted with the situation that occurred in the previous shift.

Regular reporting and tool for continuous improvement

Smart trace Control is also a unique tool for measuring the quality of delivery. By categorizing individual non-standard situations, it is possible to create statistics of provided service quality not only for internal needs. The system can report the success rate of regular lines for individual customer and evaluate each service level that was provided. “Within this statistic, a detailed breakdown of the problems encountered is also available. Management can then respond to reoccurring situations or, on the basis of these documents proactively resolve them with customer,” explains Pavel Sirotek. He adds, that delays are often caused by late loading at the customer´s end or incorrect transport documents. “This is a unique tool for measuring the quality of our services and the whole cooperation, that we present to our customers transparently,” concludes Pavel Sirotek.

Smart Trace Control was put into full operation in early July. Investment in this tool was part of development of the new IT system tailored to the needs of VCHD Cargo. Overall costs are quantified by the company to more than EUR 160 thousand.